Innovative Manufacturing Solutions for High-Quality Brake Drums with Superior Performance and Reliability

The Importance of Brake Drum Factories in Automotive Safety

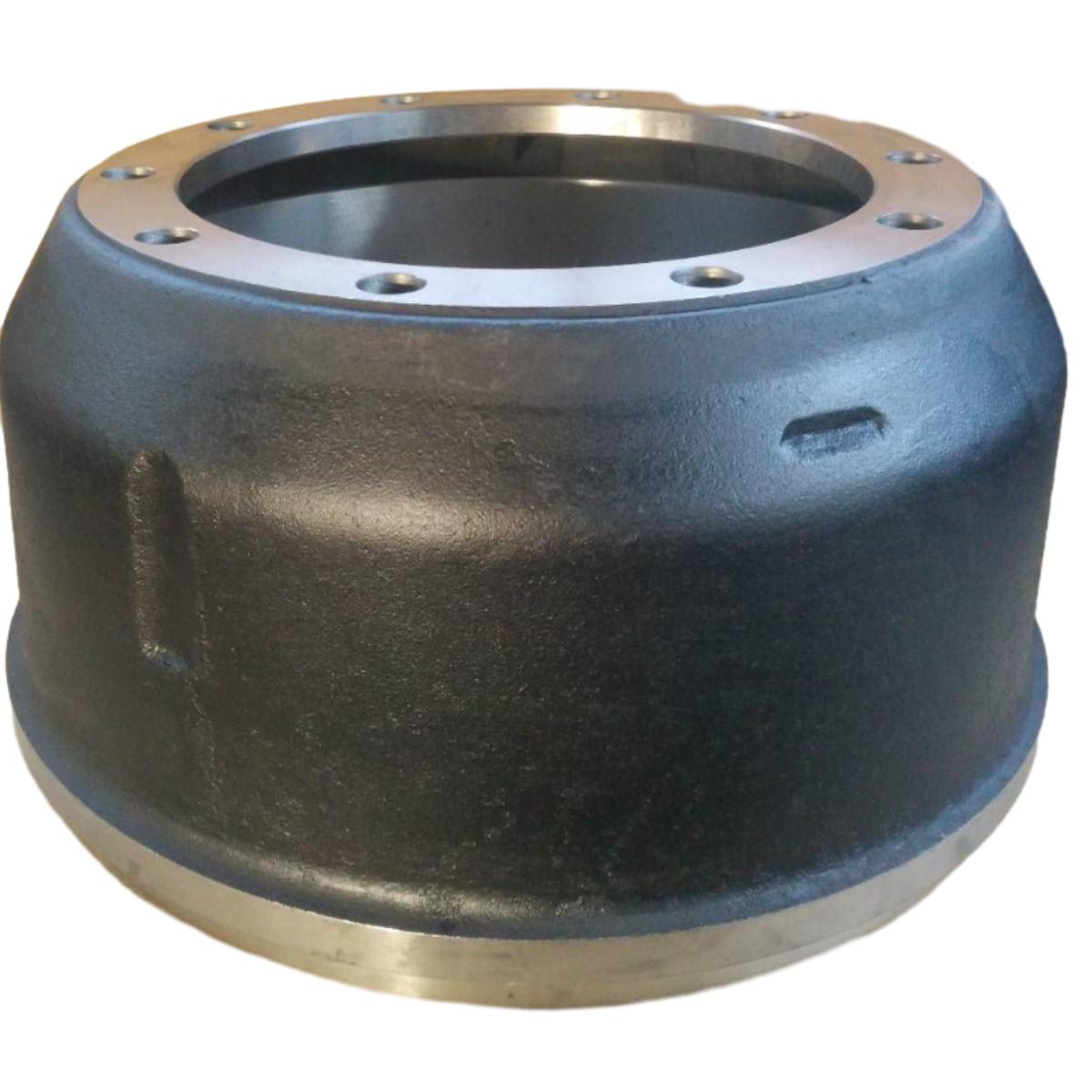

In the realm of automotive manufacturing, few components are as critical to vehicle safety as the brake system. Among the various elements that make up a brake system, brake drums play a pivotal role, especially in vehicles that utilize drum braking mechanisms. Brake drum factories, therefore, are integral to the automotive industry, ensuring that these vital parts are produced with precision, quality, and adherence to safety standards.

Understanding Brake Drums

Brake drums are circular devices that work in conjunction with brake shoes to create friction and halt a vehicle’s motion. When the brake pedal is pressed, hydraulic pressure forces the brake shoes against the inner surface of the drum, creating friction that slows the wheel's rotation. This mechanism is widely used in the rear braking systems of many cars, trucks, and other vehicles. Due to their crucial function, the quality and reliability of brake drums are paramount for road safety.

The Manufacturing Process

The manufacturing of brake drums involves several sophisticated processes. Brake drum factories typically utilize advanced technologies and materials to produce components that can withstand significant stress and wear. Initial steps often include the selection of high-quality steel or cast iron, materials known for their strength and durability. The chosen material is then subjected to melting and molding processes, followed by precision machining to achieve exact dimensions and surface finishes.

Heat treatment is another essential phase in the manufacturing process. It helps enhance the material's hardness and resistance to deformation, ultimately ensuring that the brake drums can perform effectively under varying conditions. Quality control measures are strictly enforced throughout the production cycle, with thorough inspections conducted to detect any defects or inconsistencies.

brake drum factory

Innovations and Sustainability

As technology evolves, so too do the manufacturing processes in brake drum factories. Innovations such as automated production lines and computer-aided design (CAD) are increasingly being adopted to improve efficiency and product quality. Moreover, with growing awareness of environmental concerns, manufacturers are actively seeking sustainable practices. This includes recycling waste materials and reducing energy consumption during production, all while maintaining high standards of safety and performance.

The Role of Regulation and Standards

Brake drum factories operate under stringent regulatory frameworks that vary by region. These regulations set forth safety standards that must be met to ensure that brake components are reliable. Compliance with these standards is crucial, for even minor defects in brake drums can lead to catastrophic failures, putting lives at risk. Regular audits and certifications by authoritative bodies ensure that manufacturers adhere to these regulations, thereby maintaining consumer trust and industry integrity.

Conclusion

In conclusion, brake drum factories are vital contributors to the automotive industry, producing components that are essential for safe driving. Their role in ensuring that brake drums are manufactured to the highest standards cannot be overstated. As the automotive landscape continues to evolve with advancements in technology and growing environmental considerations, these factories must adapt continuously to meet new challenges. Ultimately, the effectiveness of brake drums is directly linked to the safety of vehicles on the road, making the work conducted within these factories critical for the well-being of all road users.

-

The Power and Reliability of Brake DrumsNewsAug.27,2025

-

The High-Quality Truck Brake DrumsNewsAug.27,2025

-

Quality Brake Drums for Reliable PerformanceNewsAug.27,2025

-

Get the Quality Semi Trailer Brake Drums for Your FleetNewsAug.27,2025

-

Everything You Need to Know About Brake DrumsNewsAug.27,2025

-

Enhance Your Vehicle's Performance with Reliable Brake DrumsNewsAug.27,2025

-

Truck Drum Brake Spring Replacement ProcedureNewsAug.22,2025