SiO2 Powder-HEBEI NINGCHAI MACHINERY CO., LTD.|Rubber Reinforcement&Environmental Applications

White carbon black, also known as silicon dioxide powder, is a versatile material with wide-ranging applications across industries. This article delves into the properties, production methods, and uses of SiO₂ powder, highlighting its significance in modern manufacturing. For more information, visit the product page or explore the company website.

Understanding White Carbon Black

White carbon black, chemically represented as SiO₂, is a non-toxic, amorphous powder with unique properties. Its name derives from its white appearance, and it serves as a substitute for carbon black in various applications. The material is characterized by its high surface area, making it an excellent adsorbent and filler.

Chemical Composition and Structure

White carbon black is a porous substance with the chemical formula SiO₂·nH₂O, where nH₂O exists as surface hydroxyl groups. This structure contributes to its high reactivity and adsorption capacity. The material’s amorphous nature ensures it lacks a crystalline lattice, allowing for greater flexibility in applications.

Physical and Chemical Properties

White carbon black is a hard, brittle, non-conductive solid with a melting point of 1710°C. Its apparent density is 0.128 g/cm³, and it is insoluble in water. The material exhibits remarkable chemical stability due to the strength of the silicon-oxygen bond. However, it can react with basic oxides, alkalis, and soda ash at high temperatures to form silicates. Notably, it is resistant to most acids but can be corroded by hydrofluoric acid.

Production Methods

The production of SiO₂ powder involves two primary methods: the precipitation method and the vapor phase method.

Precipitation Method

This method involves the reaction of sodium silicate with acids to form a silica colloid. After drying and sintering, the resulting product is white carbon black. The traditional precipitation method uses sulfuric acid, hydrochloric acid, or CO₂ as reagents, while advanced techniques like super gravity technology and sol-gel methods produce high-purity silica.

Vapor Phase Method

The vapor phase method decomposes silane or siloxane at high temperatures to generate silicon nanoparticles. This process yields fumed white carbon black, which is nano-silica with a purity of up to 99% and particle sizes ranging from 10–20 nm. However, this method is complex and costly, limiting its use to specialized applications.

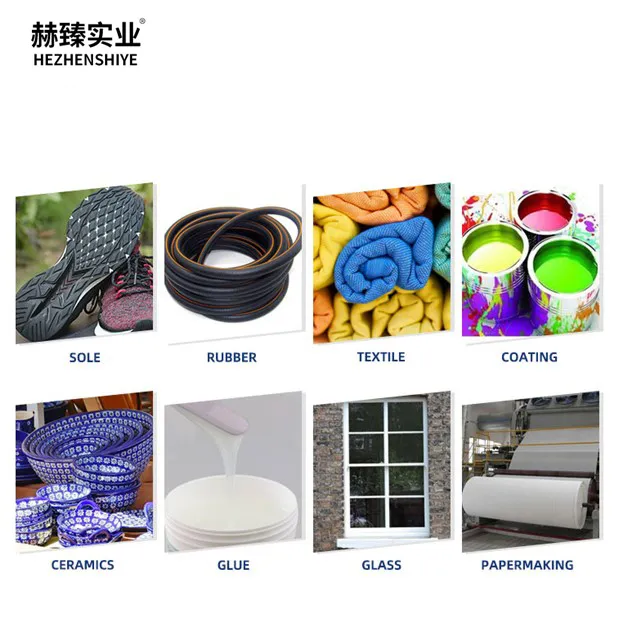

Key Applications of SiO₂ Powder

White carbon black’s versatility makes it indispensable in multiple industries. Below are its primary applications:

Rubber Industry

As a rubber reinforcing agent, SiO₂ powder accounts for over 75% of its total usage. It enhances the strength, wear resistance, and aging resistance of rubber products.

Coatings and Plastics

In the coating industry, SiO₂ powder improves adhesion, hardness, and wear resistance. Similarly, in the plastics industry, it enhances strength and aging resistance, making it ideal for durable products.

Catalyst Carrier

With its large specific surface area, SiO₂ powder serves as an effective catalyst carrier, improving catalytic performance in chemical reactions.

Environmental Protection

The material acts as an adsorbent, removing harmful substances from water. It also participates in photocatalytic reactions to degrade pollutants in air and water, contributing to environmental sustainability.

Biomedical and Pharmaceutical Uses

Biocompatible and non-toxic, SiO₂ powder is used in biomedical applications such as drug carriers and bone replacement materials. In the pharmaceutical industry, it enhances drug dispersion and bioavailability.

Market Trends and Industry Insights

The precipitated white carbon black market in China has shown a recovery trend, driven by increased demand and improved pricing. Companies with strong R&D capabilities and high-quality products are expanding their market share. Brand reputation remains a critical factor in the carbon black industry.

According to NIST (National Institute of Standards and Technology), standards for material properties play a vital role in ensuring product reliability. NIST’s research on nanomaterials and chemical stability underscores the importance of precise measurements in industrial applications. For more details, visit the NIST website.

Product Specifications

| Parameter | ବିବରଣୀ |

|---|---|

| CAS No. | 112945-52-5 |

| Place of Origin | China |

| Color | White |

| Shape | Powder |

| Purity | 95–99% |

| Grade | Industrial Grade |

| Package | 10–25 kg/bag, customized |

| MOQ | 1 kg |

Company Background

HEBEI NINGCHAI MACHINERY CO., LTD. is a leading manufacturer of industrial materials, specializing in SiO₂ powder and related products. The company’s commitment to quality and innovation has established it as a trusted supplier in the global market. For more information about their products, visit the company page.

Conclusion

SiO₂ powder is a critical material in modern industry, offering unparalleled versatility and performance. From enhancing rubber products to environmental remediation, its applications are vast. As the market continues to evolve, HEBEI NINGCHAI MACHINERY CO., LTD. remains at the forefront, delivering high-quality solutions. For detailed specifications or to place an order, explore the product page.

References

NIST (National Institute of Standards and Technology) provides standards and research to ensure material reliability. For more information, visit https://www.nist.gov.

-

truck-drum-brake-spring-replacement-procedureସମ୍ବାଦAug.22,2025

-

evolution-of-brake-drum-function-designs-in-automotive-historyସମ୍ବାଦAug.22,2025

-

drum-brake-motor-thermal-management-solutionsସମ୍ବାଦAug.22,2025

-

essential-tools-for-brakes-and-drums-repair-jobsସମ୍ବାଦAug.22,2025

-

trailer-drum-brake-self-adjusting-mechanisms-explainedସମ୍ବାଦAug.22,2025

-

brake-drum-types-in-vintage-auto-restorationସମ୍ବାଦAug.22,2025

-

Rear Drum Brakes Maintenance Tipsସମ୍ବାଦAug.04,2025