When people ask, what are drum brakes, they’re often surprised to learn that this traditional braking system remains widely used today. Drum brakes function by using brake shoes that press outward against the inner surface of a spinning drum attached to the wheel. This friction slows and eventually stops the vehicle. Though more modern disc brakes are now common on front axles, many vehicles, especially trucks and economy cars, still rely on drum brakes for the rear axle.

One reason drum brakes endure is their cost-effectiveness. The manufacturing and maintenance of drum brakes are generally cheaper compared to disc systems. They also offer better protection from dust and moisture due to their enclosed design, which makes them especially ideal for use in dirty or off-road environments. This design also makes them advantageous for applications requiring integrated parking brakes, as the self-contained nature allows for simpler mechanisms.

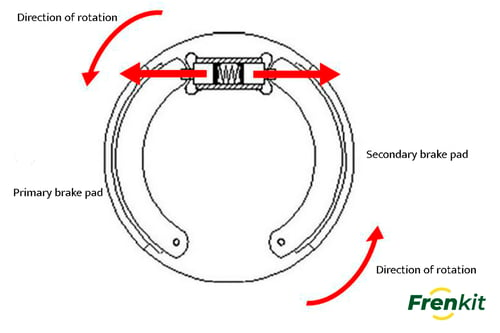

Another key point when answering what are drum brakes is their braking power at low speeds. Drum brakes are self-energizing, meaning the rotational force of the drum can assist in pulling the brake shoe tighter against the drum, reducing the amount of force needed from the driver. While they may not dissipate heat as efficiently as disc brakes under intense use, drum brakes are excellent for rear applications where less braking force is required.

So, while the automotive world constantly innovates, drum brakes maintain a unique and valued position in today’s vehicles—offering durability, reliability, and budget-friendly performance.

Understanding the Average Cost of a Drum Brake Job: Budgeting for Maintenance

If you’re researching the average cost drum brake job, you’ll find that it generally ranges between $150 to $400 per axle, depending on your vehicle type, local labor rates, and whether you’re using OEM or aftermarket parts. Compared to disc brakes, drum brake maintenance is usually more affordable, especially for rear-axle systems.

For a basic replacement, costs often break down into labor and parts. Labor typically ranges from $80 to $150, depending on location and service center rates. The remaining cost includes shoes, hardware kits, and potentially drums if they need resurfacing or replacement. Rear drum brakes also include parking brake mechanisms, which may require additional servicing.

Some vehicles may experience drum brake job costs at the higher end of the scale if they involve performance components, such as high-grade ceramic shoes or premium rust-resistant drums. Hybrid and electric vehicles may also incur higher costs due to their specific parts and assembly requirements.

DIY enthusiasts may bring costs down by handling the labor themselves, though it's vital to have the correct tools and mechanical knowledge. If you're not confident, it's worth investing in a professional service to avoid costly mistakes and ensure safety.

Overall, knowing the average cost drum brake job helps vehicle owners budget accordingly and avoid surprises. Regular inspections and timely service prevent more expensive repairs and ensure consistent performance.

Top Drum Brake Suppliers: Where Quality and Reliability Begin

In a competitive marketplace, finding reputable drum brake suppliers is key to ensuring that the braking systems on your vehicle or fleet are safe, durable, and effective. Whether you’re a mechanic, automotive parts distributor, or vehicle owner, working with dependable suppliers is non-negotiable.

Leading drum brake suppliers offer a wide variety of components, including brake shoes, drums, wheel cylinders, springs, and hardware kits. These suppliers often provide both OEM-grade and aftermarket solutions, allowing buyers to choose between affordability and top-tier performance depending on their needs.

What sets great drum brake suppliers apart is their commitment to quality control. The best manufacturers use automated inspection systems, metallurgical testing, and precise measurements to ensure that each drum and shoe pair functions flawlessly under pressure and high temperatures. Many also comply with international standards such as ISO, QS, and SAE, ensuring consistent quality across global markets.

In addition to manufacturing prowess, modern drum brake suppliers are increasingly focused on logistics and service. With the rise of online ordering and global distribution, having real-time stock information, on-time shipping, and responsive customer service is just as crucial as the parts themselves.

If you’re in the market for dependable braking components, choose drum brake suppliers with proven track records, technical support, and a wide catalog of compatible parts. Whether you manage a small repair shop or an industrial fleet, aligning with a reliable supplier can save you time, money, and potential safety risks.

How to Choose the Right Drum Brake System for Your Vehicle

Choosing the right drum brake components involves more than just checking your vehicle’s model number. It requires a clear understanding of your driving conditions, performance needs, and budget. Whether you're looking to restore an older car or maintain a modern work truck, knowing your options from drum brake suppliers ensures optimal performance and safety.

First, always match the brake shoe and drum size to the manufacturer’s specifications. Using mismatched or undersized components can lead to uneven braking, increased wear, and potential failure. High-mileage or high-load vehicles should consider premium materials like semi-metallic or ceramic shoes for better heat resistance and longevity.

If you live in areas with wet or salty conditions, rust-resistant drums—such as zinc-coated or powder-coated options—can greatly extend the life of your brakes. Some drum brake suppliers even offer specialized coatings to protect against corrosion and improve thermal performance.

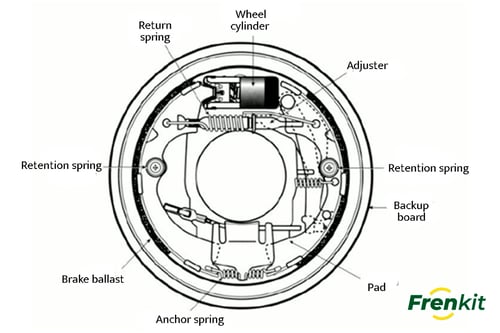

Don’t overlook the hardware. Springs, adjusters, and retainers may seem insignificant, but they play a crucial role in drum brake operation. Replacing them during a brake job ensures balanced braking force and noise-free performance.

Lastly, factor in your driving style. Aggressive drivers or those towing heavy loads should opt for performance-rated brake shoes and drums, which handle repeated stops without fading. Routine drivers may find economy-grade parts suitable, offering good performance at a lower cost.

What Are Drum Brakes vs Disc Brakes: A Comparative Insight

While this article focuses on what are drum brakes, it's helpful to understand how they compare to disc brakes in function and application. Drum brakes use internal shoes that expand outward to contact the drum, while disc brakes clamp pads onto a rotor. Each has distinct advantages and disadvantages.

Drum brakes are typically more cost-effective to produce and service. They offer self-energizing braking, meaning the brake shoe action is amplified by the drum’s rotation. This requires less hydraulic pressure and reduces the size and complexity of the master cylinder and related components.

They also integrate easily with parking brake systems, especially in the rear axle, where lighter braking is needed. The enclosed design keeps debris and moisture out, enhancing durability in challenging environments.

However, drum brakes are more prone to heat buildup under prolonged or aggressive braking, which can lead to brake fade. Disc brakes, with their exposed rotors, allow for better cooling and consistent performance during high-speed or high-pressure braking scenarios.

Modern vehicles often use a combination of both: disc brakes in the front, where most braking force is required, and drum brakes in the rear to manage balance and budget. Understanding what are drum brakes and how they fit within the broader braking system helps you make informed decisions about maintenance and upgrades.

FAQs

What are drum brakes and how do they differ from disc brakes?

Drum brakes use curved brake shoes that press against the inside of a rotating drum to create friction and stop the vehicle. Disc brakes, on the other hand, use pads that clamp onto a spinning disc or rotor. Drum brakes are enclosed, less expensive, and ideal for rear-wheel use, while disc brakes offer better heat dissipation and performance at higher speeds.

How often should drum brakes be serviced or replaced?

On average, drum brake shoes should be inspected every 20,000 to 30,000 miles and replaced when worn. Drums themselves can last longer, often up to 100,000 miles, depending on driving habits and conditions. Regular maintenance and cleaning of the drum assembly help prolong the lifespan of all components.

What is the average cost drum brake job for front and rear axles?

The average cost drum brake job ranges from $150 to $400 per axle. This includes labor and parts such as brake shoes, drums, and hardware. Costs vary based on vehicle model, local labor rates, and whether you choose OEM or aftermarket parts. Rear drum brake jobs are typically more common and often less expensive than front repairs.

Where can I find reputable drum brake suppliers?

You can find reliable drum brake suppliers through authorized automotive parts distributors, online retailers, and OEM networks. Look for suppliers with positive customer reviews, certification credentials (ISO, QS), and strong technical support. Brands that offer warranty-backed components and global shipping options are also ideal.

Can drum brake parts be customized or painted for performance or aesthetics?

Yes. Many drivers opt for custom-painted drums for aesthetic appeal, especially if the wheels expose the braking system. Performance upgrades like ceramic or semi-metallic brake shoes, coated drums, and stainless-steel hardware are also available. However, all customizations should use materials rated for high temperatures and automotive use to ensure safety and reliability.