Understanding the Components of Truck Drum Brake Systems through Diagram Analysis

Understanding Truck Drum Brake Systems Through Diagrams

When it comes to the safety and functionality of heavy-duty vehicles, the braking system plays a crucial role. Among various types of braking systems, the drum brake system is a common choice for trucks due to its reliability and effectiveness. This article aims to provide a comprehensive understanding of truck drum brake systems, using diagrams as a reference to illustrate key components and their functions.

Basic Components of a Drum Brake System

At its core, a truck drum brake system consists of several key components the brake drum, brake shoes, wheel cylinder, springs, and the backing plate. Each of these parts plays a vital role in how the braking system operates, contributing to the overall performance and efficiency of the vehicle.

1. Brake Drum The brake drum is a cylindrical component that rotates with the wheel. It is typically made of cast iron or steel and provides a surface against which the brake shoes press to create friction and stop the vehicle.

2. Brake Shoes Attached to the backing plate, brake shoes are the friction elements of the drum brake system. When braking is applied, these shoes expand outward against the inner surface of the brake drum, generating the necessary friction to slow down or stop the truck.

3. Wheel Cylinder This component is a crucial part of the hydraulic system in drum brakes. It contains pistons that push the brake shoes outward. When the brake pedal is pressed, hydraulic fluid flows into the wheel cylinder, causing the pistons to expand and the brake shoes to contact the drum.

4. Springs Springs are used to retract the brake shoes after the brake is released. They ensure that the shoes do not drag against the drum when not in use, which helps to enhance fuel efficiency and reduce wear on the brake components.

5. Backing Plate The backing plate serves as the foundation to which the other brake components are attached. It is designed to provide structural support while also protecting against dirt and debris, which can affect the performance of the braking system.

The Working Principle

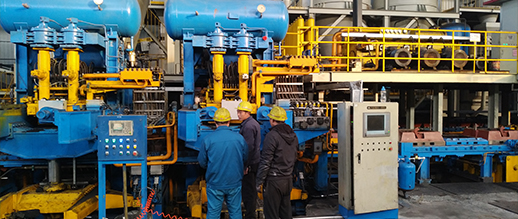

truck drum brake diagram

The functioning of drum brakes can be encapsulated in a few simple steps, illustrating the process visually through a diagram

1. Brake Application When the driver applies the brake pedal, hydraulic pressure is sent to the wheel cylinder. This action can be depicted in a diagram showing fluid movement from the master cylinder to the wheel cylinder.

2. Expansion of Brake Shoes The hydraulic pressure causes the pistons inside the wheel cylinder to move outward, which in turn pushes the brake shoes against the inner surface of the brake drum. In a diagram, this can be illustrated with arrows indicating the outward motion of the brake shoes.

3. Friction and Stopping Power As the brake shoes engage with the spinning drum, they create friction. This heat and friction work together to slow down the truck. A diagram might highlight the contact area between the shoes and the drum, emphasizing the points of contact and the force applied.

4. Release of Brakes After the brake pedal is released, the springs retract the brake shoes back to their original position, away from the drum. This can be depicted in a diagram showing the return path of the brake shoes with arrows indicating the movement caused by the retracting springs.

Advantages of Drum Brakes

Drum brakes offer several advantages, particularly for heavy vehicles like trucks. They provide strong stopping power, can withstand more heat than disc brakes without fading, and have a more compact design, which is beneficial in limited space applications. Additionally, they are generally more cost-effective in terms of maintenance and replacement.

Conclusion

Understanding truck drum brake systems is essential for anyone involved in the maintenance or design of heavy-duty vehicles. By examining the various components, their functions, and the overall working principle through diagrams, one can appreciate the complexity and importance of this vital safety feature. As technology continues to evolve, the truck drum brake system remains a testament to the ingenuity of automotive engineering, ensuring that these powerful vehicles operate safely and efficiently on our roads.

-

The Power and Reliability of Brake DrumsNewsAug.27,2025

-

The High-Quality Truck Brake DrumsNewsAug.27,2025

-

Quality Brake Drums for Reliable PerformanceNewsAug.27,2025

-

Get the Quality Semi Trailer Brake Drums for Your FleetNewsAug.27,2025

-

Everything You Need to Know About Brake DrumsNewsAug.27,2025

-

Enhance Your Vehicle's Performance with Reliable Brake DrumsNewsAug.27,2025

-

Truck Drum Brake Spring Replacement ProcedureNewsAug.22,2025