-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Understanding the Functionality and Importance of Industrial Drum Brakes in Heavy Machinery Operations

Understanding Industrial Drum Brakes Efficiency and Safety in Heavy-Duty Applications

Industrial drum brakes play a pivotal role in various heavy-duty applications, providing essential safety and control in machinery and vehicles. These brakes are commonly utilized in industries ranging from manufacturing to transportation, where the requirement for reliable stopping power is paramount. This article aims to explore the components, functionality, advantages, and applications of industrial drum brakes.

Components of Industrial Drum Brakes

At their core, industrial drum brakes consist of several key components the drum itself, brake shoes, a hydraulic or pneumatic actuator, and various linkages. The drum, usually made from strong materials like cast iron or composite metals, rotates with the wheel or drive mechanism. The brake shoes, situated inside the drum, are lined with friction materials that provide the actual stopping force when engaged.

The engagement of the brake shoes is typically controlled by an actuator, which can operate through hydraulic or pneumatic means. When the operator initiates braking, the actuator pushes the shoes outward against the inner surface of the drum, creating friction that slows down or stops the motion of the equipment.

Functionality of Drum Brakes

The working principle of drum brakes revolves around friction. When the brakes are applied, the shoes press against the drum, generating resistance and converting kinetic energy into thermal energy. This process effectively reduces the speed of the moving machinery or vehicle. The design of the drum brake allows for consistent braking power and is less prone to fading under heavy use, making it suitable for industrial environments where safety and reliability are critical.

One of the additional features of industrial drum brakes is their ability to self-energize. This means that as the drum rotates, it can help push the brake shoes against the drum more forcefully, increasing the braking efficiency without requiring excessive force from the operator.

Advantages of Industrial Drum Brakes

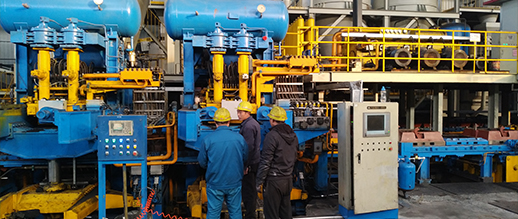

industrial drum brakes

Industrial drum brakes offer several significant advantages over other braking systems, such as disc brakes. Primarily, they are known for their durability and longevity. The enclosed design of the drum helps protect the braking mechanism from debris and harsh environmental conditions, leading to less wear and tear.

Moreover, drum brakes typically provide a larger surface area for friction, allowing for effective reduction of speed. This characteristic is especially beneficial in heavy-duty applications, where loads can be substantial. Drum brakes also tend to be more cost-effective, both regarding initial installation and maintenance.

Applications of Industrial Drum Brakes

The applications of industrial drum brakes are diverse and extensive. They are widely used in various sectors including, but not limited to

1. Manufacturing Equipment Drum brakes are commonly installed in factory machinery such as conveyor systems and lifting equipment where precise control is necessary to prevent accidents.

2. Construction Vehicles Heavy machinery like cranes, excavators, and forklifts rely on drum brakes for their ability to manage high loads efficiently.

3. Rail Transportation Many trains utilize drum brakes for their reliability in stopping large, heavy passenger and freight cars safely.

4. Agricultural Equipment Tractors and other farming machinery benefit from drum brakes, particularly when operating in challenging outdoor conditions.

In conclusion, industrial drum brakes are a crucial component in maintaining safety and efficiency across various industries. Their design offers durability, effective stopping power, and adaptability to tough environments, ensuring that operators can rely on them to perform consistently under demanding conditions. As industries continue to evolve, the integration of advanced materials and technologies into drum brake systems will likely enhance their performance and effectiveness in the years to come.

-

What Are Drum BrakesNewsJul.07,2025

-

Understanding Brake Drum MaterialNewsJul.07,2025

-

Semi-Trailer Brake Drum: A Key Component for Extreme Loads and Long-Distance TransportNewsJul.07,2025

-

Drum Brake Pads for SaleNewsJul.07,2025

-

Brake Drums for SaleNewsJul.07,2025

-

Brake Drum ManufacturerNewsJul.07,2025

-

Aluminum Brake Drums: The Future of High-Performance CarsNewsJul.07,2025