-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

anglisht

anglisht -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

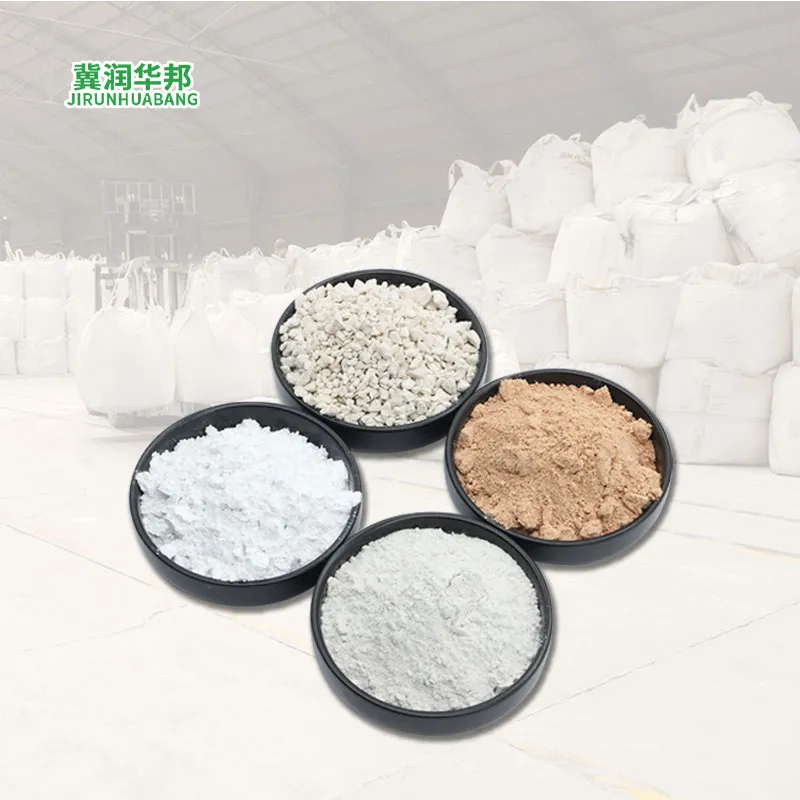

High Resistivity Kaolin-Ceramic Glaze Paper Coating|Ceramic Glaze, Paper Coating

High-resistivity kaolin, a naturally occurring clay mineral, has become an essential component in modern industrial processes, particularly in the ceramic and paper industries. Its unique properties—such as high electrical resistivity, fine particle size, and chemical inertness—make it an ideal raw material for advanced glaze formulations and paper coatings. This article explores the technical specifications, applications, and benefits of Runhuabang High Resistivity Kaolin, while highlighting the role of NIST in establishing industry standards for materials like kaolin.

Understanding High-Resistivity Kaolin: A Natural Industrial Workhorse

High-resistivity kaolin is a specialized form of kaolin clay characterized by its exceptional electrical insulation properties. Unlike standard kaolin, which may contain impurities that reduce its resistivity, high-resistivity kaolin undergoes purification processes to enhance its performance. This makes it particularly valuable in applications where electrical stability is critical, such as in ceramic glazes and paper coatings. The mineral's natural plasticity and firing characteristics further contribute to its versatility, enabling it to meet the demands of diverse industrial applications.

The Runhuabang High Resistivity Kaolin is sourced from high-quality deposits in China and is processed to ensure consistency in purity and performance. Its technical specifications reflect its suitability for both industrial and commercial use.

High-resistivity kaolin's natural properties make it an ideal material for advanced industrial applications.

Technical Specifications of Runhuabang High Resistivity Kaolin

| Parameter | Detajet |

|---|---|

| CAS No. | 1332-58-7 |

| Place of Origin | China |

| Color | White/Yellow |

| Shape | Powder |

| Purity | 90-97% |

| Grade | Cosmetics Grade/Industrial Grade |

| Package | 5-25kg/bag, Customized Package |

| MOQ | 1kg |

Applications in Ceramic Glaze Formulations

In the ceramic industry, Runhuabang High Resistivity Kaolin plays a critical role in glaze formulations. Its high electrical resistivity ensures that the glaze remains stable during the firing process, preventing unwanted electrical currents that could compromise the glaze's uniformity and appearance. This stability is essential for producing ceramics with a smooth, defect-free surface.

Additionally, kaolin's natural plasticity and firing properties contribute to the development of strong, durable ceramic bodies. When combined with other raw materials, high-resistivity kaolin enhances the glaze's adhesion to the ceramic substrate, reducing the risk of cracking or peeling during use. This makes it a preferred choice for manufacturers of high-quality ceramics, including tableware, sanitary ware, and industrial ceramics.

The fine particle size of high-resistivity kaolin ensures excellent dispersion in glaze formulations.

Advancements in Paper Coating Applications

For paper manufacturers, Runhuabang High Resistivity Kaolin offers a smooth, uniform surface that enhances printability and opacity. Its fine particle size and platelet structure allow for excellent dispersion and coverage, resulting in high-quality paper with superior ink holdout and brightness. This is particularly beneficial for applications such as high-end printing papers, packaging materials, and specialty papers.

The chemical inertness of high-resistivity kaolin ensures compatibility with various coating chemistries, making it a versatile and reliable raw material for paper manufacturers. By incorporating this kaolin into their formulations, companies can achieve consistent quality, reduce production costs, and meet the evolving demands of the market.

High-resistivity kaolin's chemical stability makes it ideal for paper coating applications.

Why Choose Runhuabang High Resistivity Kaolin?

Runhuabang's high-resistivity kaolin is engineered to meet the stringent requirements of modern industrial applications. Here are some key advantages:

- Enhanced Electrical Stability: The high resistivity of the kaolin ensures minimal electrical interference during ceramic firing and paper coating processes.

- Superior Dispersion: The fine particle size and platelet structure allow for even distribution in formulations, improving the final product's performance.

- Chemical Inertness: This property ensures compatibility with a wide range of coating and glaze chemistries.

- Customizable Packaging: The product is available in various packaging options, including 5-25kg bags and customized solutions to meet specific customer needs.

These features position Runhuabang High Resistivity Kaolin as a preferred choice for industries seeking reliable and high-performance materials.

Company Background: Hebei Ningchai Machinery Co., Ltd.

Hebei Ningchai Machinery Co., Ltd., the manufacturer of Runhuabang High Resistivity Kaolin, is a leading supplier of industrial materials in China. With decades of experience in the production and distribution of high-quality kaolin products, the company has established itself as a trusted partner for manufacturers in the ceramic and paper industries.

Hebei Ningchai's commitment to innovation and quality assurance ensures that its products meet international standards. The company's state-of-the-art facilities and rigorous quality control processes guarantee that Runhuabang High Resistivity Kaolin consistently delivers superior performance and reliability.

The Role of NIST in Industrial Material Standards

The National Institute of Standards and Technology (NIST) plays a critical role in establishing and maintaining standards for industrial materials, including clay minerals like kaolin. According to NIST, precise measurements and standardized testing procedures are essential for ensuring the quality and consistency of materials used in manufacturing processes. This is particularly relevant for high-resistivity kaolin, where even minor variations in composition can impact performance.

NIST's work in metrology and materials science provides a foundation for industries to develop and refine their products. By adhering to NIST guidelines, manufacturers like Hebei Ningchai can ensure that their materials meet the highest standards of quality and reliability.

Conclusion: A Reliable Solution for Modern Industries

Runhuabang High Resistivity Kaolin exemplifies the potential of natural materials to meet the demands of advanced industrial applications. Its unique combination of electrical stability, chemical inertness, and versatility makes it an indispensable resource for ceramic and paper manufacturers. As industries continue to evolve, the importance of high-quality materials like high-resistivity kaolin will only grow.

For more information about Runhuabang High Resistivity Kaolin and its applications, visit the Hebei Ningchai Machinery Co., Ltd. website. Discover how this innovative material can enhance your industrial processes and drive sustainable growth.

References

National Institute of Standards and Technology (NIST). (n.d.). Standards and Measurements. Retrieved from https://www.nist.gov.

-

Rear Drum Brakes Maintenance TipsLajmeAug.04,2025

-

Key Components Affecting Brake Drum FunctionLajmeAug.04,2025

-

Important Inspection for Truck Drum BrakeLajmeAug.04,2025

-

How to Prepare for Changing Rear Drum BrakesLajmeAug.04,2025

-

Essential Tools for Cleaning Drum Brakes ProperlyLajmeAug.04,2025

-

Brake Drum Function GuideLajmeAug.04,2025

-

Safety Features of Red Brake DrumsLajmeAug.01,2025