High-Resistivity Kaolin-Ceramic Glaze & Paper Coating|HEBEI NINGCHAI MACHINERY CO.,LTD.

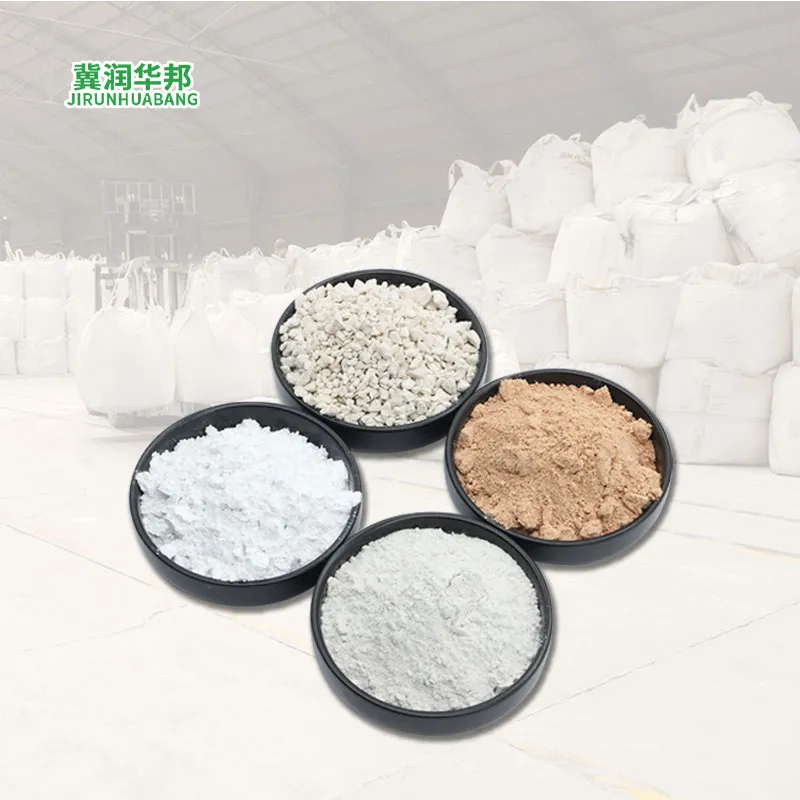

High-resistivity kaolin is a critical raw material in modern industrial applications, particularly in the ceramic and paper coating industries. This naturally occurring clay mineral, known for its exceptional electrical resistance and physical properties, has become a cornerstone for manufacturers seeking high-performance materials. Runhuabang, a leading provider of kaolin solutions, offers premium high-resistivity kaolin that meets the demands of diverse industrial processes. This article explores the unique features, technical specifications, and applications of this versatile material, supported by insights from authoritative sources like the National Institute of Standards and Technology (NIST).

Understanding High-Resistivity Kaolin: Key Features and Benefits

High-resistivity kaolin is a specialized form of kaolin clay engineered to exhibit exceptional electrical insulation properties. Unlike conventional kaolin, which may contain impurities that reduce its resistivity, this variant is processed to ensure minimal conductivity. This characteristic is particularly vital in ceramic glaze formulations, where electrical stability during firing is essential. According to NIST, materials with high resistivity are critical for applications requiring minimal energy loss and enhanced durability.

In the ceramic industry, high-resistivity kaolin contributes to the development of smooth, uniform glazes by preventing unwanted electrical currents during the firing process. Its natural plasticity and firing properties also enhance the strength and durability of ceramic bodies. For paper coating applications, this material provides a smooth, uniform surface that improves printability, opacity, and ink holdout. The fine particle size and platelet structure of high-resistivity kaolin ensure excellent dispersion, resulting in high-quality paper with superior brightness and coverage.

In the ceramic industry, high-resistivity kaolin contributes to the development of smooth, uniform glazes by preventing unwanted electrical currents during the firing process. Its natural plasticity and firing properties also enhance the strength and durability of ceramic bodies. For paper coating applications, this material provides a smooth, uniform surface that improves printability, opacity, and ink holdout. The fine particle size and platelet structure of high-resistivity kaolin ensure excellent dispersion, resulting in high-quality paper with superior brightness and coverage.

Kaolin benefits for skin and kaolin clay benefits for face are often highlighted in cosmetic applications, but its industrial uses are equally significant. The chemical inertness of high-resistivity kaolin ensures compatibility with various coating chemistries, making it a reliable choice for paper manufacturers. This versatility, combined with its high purity (90-97%), positions it as a preferred material for both industrial and high-tech applications.

Technical Specifications: A Detailed Overview

| Parameter | Lintlha |

|---|---|

| CAS No. | 1332-58-7 |

| Place of Origin | China |

| Color | White/Yellow |

| Shape | Powder |

| Purity | 90-97% |

| Grade | cosmetics grade/industrial Grade |

| Package | 5-25kg/bag, customized package |

| MOQ | 1kg |

The technical specifications of high-resistivity kaolin underscore its suitability for demanding applications. The product parameters highlight its adaptability, with options for both industrial and cosmetic-grade usage. The availability of customized packaging and low minimum order quantities (MOQ) further enhances its accessibility for manufacturers of all scales.

Industrial Applications: Ceramic Glaze and Paper Coating

High-resistivity kaolin is a vital component in ceramic glaze formulations. Its ability to maintain stability during high-temperature firing ensures that glazes retain their smooth, uniform appearance. This is critical for industries producing ceramics with precise aesthetic and functional requirements, such as tableware, sanitaryware, and technical ceramics. NIST research on ceramic materials emphasizes the importance of resistivity in preventing defects during the manufacturing process.

In the paper industry, high-resistivity kaolin is used to enhance the quality of coated papers. The fine particle size and platelet structure of this material allow for even distribution, improving printability and opacity. This makes it ideal for applications such as high-quality printing papers, packaging materials, and specialty papers. The chemical inertness of the material also ensures compatibility with a wide range of coating formulations, reducing the risk of adverse reactions.

In the paper industry, high-resistivity kaolin is used to enhance the quality of coated papers. The fine particle size and platelet structure of this material allow for even distribution, improving printability and opacity. This makes it ideal for applications such as high-quality printing papers, packaging materials, and specialty papers. The chemical inertness of the material also ensures compatibility with a wide range of coating formulations, reducing the risk of adverse reactions.

The benefits of white kaolin clay extend beyond its physical properties. Its natural abundance and cost-effectiveness make it a sustainable choice for manufacturers. Additionally, the ability to customize the product for specific applications ensures that it meets the unique needs of different industries.

Company Background: Hebei Ningchai Machinery Co., Ltd.

As a trusted provider of industrial materials, Hebei Ningchai Machinery Co., Ltd. has established itself as a leader in the production and supply of high-quality kaolin products. With a focus on innovation and customer satisfaction, the company ensures that its offerings meet the highest standards of purity, performance, and reliability. Their commitment to quality is reflected in the product specifications and the diverse range of applications for which their kaolin is suited.

The company's expertise in material science and manufacturing processes enables it to deliver products that consistently meet the demands of the ceramic and paper industries. By leveraging advanced technologies and rigorous quality control measures, Hebei Ningchai Machinery Co., Ltd. ensures that its high-resistivity kaolin is a reliable choice for manufacturers worldwide.

The company's expertise in material science and manufacturing processes enables it to deliver products that consistently meet the demands of the ceramic and paper industries. By leveraging advanced technologies and rigorous quality control measures, Hebei Ningchai Machinery Co., Ltd. ensures that its high-resistivity kaolin is a reliable choice for manufacturers worldwide.

Conclusion: The Future of High-Resistivity Kaolin in Industrial Applications

High-resistivity kaolin is a material that bridges the gap between traditional and modern industrial needs. Its unique combination of electrical resistance, chemical inertness, and physical properties makes it indispensable in ceramic glaze and paper coating applications. As industries continue to evolve, the demand for high-performance materials like this will only grow. NIST's research on material science underscores the importance of such innovations in driving technological progress.

For manufacturers seeking a reliable and versatile raw material, Runhuabang's high-resistivity kaolin offers a compelling solution. With its exceptional technical specifications and wide range of applications, this material is poised to play a critical role in the future of industrial manufacturing.

References

National Institute of Standards and Technology (NIST). "Advancing Technology Through Measurement Science." Retrieved from https://www.nist.gov/.

Keywords: benefits of white clay, benefits of white kaolin clay, kaolin benefits for skin, kaolin clay benefits for face.

-

Truck Drum Brake Spring Replacement ProcedureLitabaAug.22,2025

-

Evolution Of Brake Drum Function Designs In Automotive HistoryLitabaAug.22,2025

-

Drum Brake Motor Thermal Management SolutionsLitabaAug.22,2025

-

Essential tools for brakes and drums repair jobsLitabaAug.22,2025

-

Trailer Drum Brake Self-Adjusting Mechanisms ExplainedLitabaAug.22,2025

-

Brake Drum Types in Vintage Auto RestorationLitabaAug.22,2025

-

Rear Drum Brakes Maintenance TipsLitabaAug.04,2025