High-Resistivity Kaolin-Ceramic Glazes & Paper Coatings|HEBEI NINGCHAI MACHINERY CO.,LTD.

Introduction

In the ever-evolving landscape of industrial materials, high-resistivity kaolin has emerged as a critical component in both the ceramic and paper industries. Renowned for its unique properties, this naturally occurring clay mineral plays a pivotal role in enhancing the quality and performance of products ranging from ceramic glazes to high-quality paper coatings. This article delves into the features, advantages, and applications of high-resistivity kaolin, while also exploring the company behind its production, HEBEI NINGCHAI MACHINERY CO.,LTD.

Understanding High-Resistivity Kaolin

High-resistivity kaolin is a specialized form of kaolin clay characterized by its exceptional electrical resistivity. This property makes it particularly suitable for applications where electrical stability is paramount. Unlike standard kaolin, which may exhibit lower resistance, high-resistivity kaolin ensures that ceramic glazes and paper coatings maintain their integrity under various conditions. According to the National Institute of Standards and Technology (NIST), the development of materials with precise electrical properties is essential for advancing industrial processes, and high-resistivity kaolin exemplifies this principle [1].

The mineral's natural plasticity and firing characteristics further enhance its utility. In ceramics, it contributes to the formation of strong, durable bodies with excellent glaze adherence. For paper coatings, its fine particle size and platelet structure allow for superior dispersion and coverage, resulting in enhanced printability and opacity. These attributes make it a preferred choice for manufacturers seeking to optimize their production processes.

Key Features and Advantages

One of the most significant advantages of high-resistivity kaolin is its ability to prevent unwanted electrical currents during the firing process of ceramic glazes. This stability ensures a smooth, uniform appearance, which is critical for high-quality ceramic products. Additionally, its chemical inertness allows it to remain compatible with a wide range of coating chemistries, making it a versatile material for various industrial applications.

For paper manufacturers, the fine particle size of high-resistivity kaolin translates to improved ink holdout and brightness. The platelet structure of the mineral enables it to create a smooth, even surface, which enhances the overall quality of the paper. This is particularly important in the production of high-end printing papers, where visual appeal and durability are key factors.

Technical Specifications

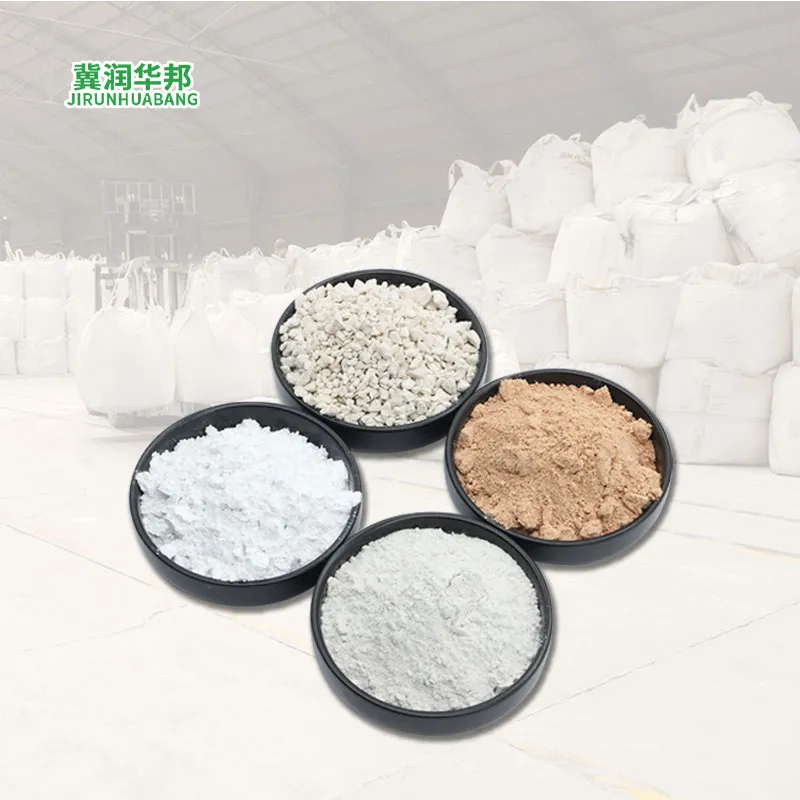

The following table provides a detailed overview of the high-resistivity kaolin product's specifications:

| Parameter | Lintlha |

|---|---|

| CAS No. | 1332-58-7 |

| Place of Origin | China |

| Color | White/Yellow |

| Shape | Powder |

| Purity | 90-97% |

| Grade | Cosmetics Grade/Industrial Grade |

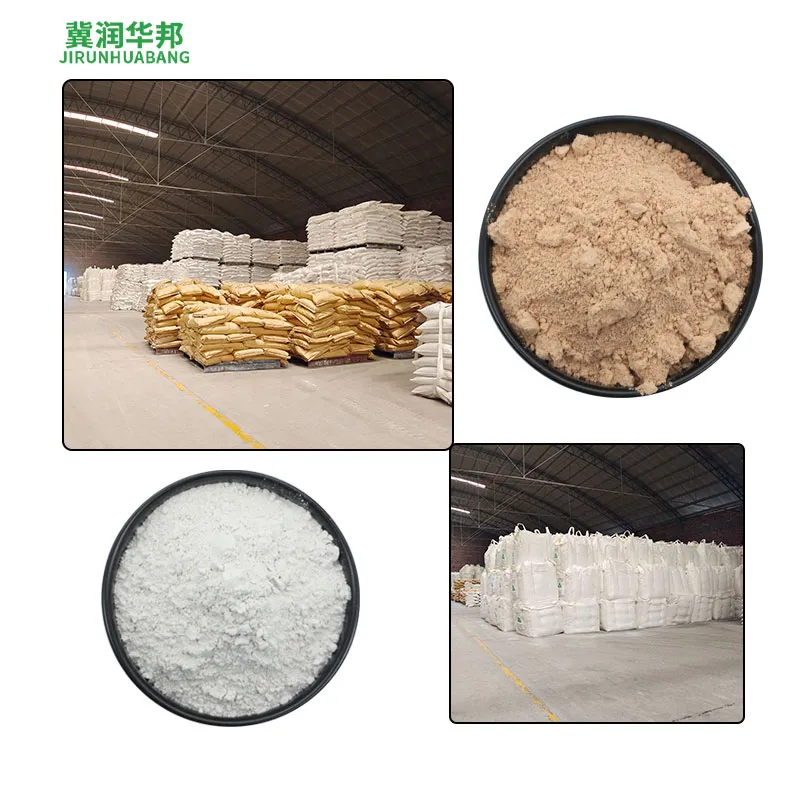

| Package | 5-25kg/bag, customized package |

| MOQ | 1kg |

These specifications highlight the product's versatility and adaptability to different industrial requirements. The high purity and customizable packaging options make it suitable for both small-scale and large-scale production environments.

Applications in Ceramic Glazes

In the ceramic industry, high-resistivity kaolin is a cornerstone material for glaze formulations. Its high electrical resistivity ensures that the glaze remains stable during the firing process, preventing disruptions that could compromise the final product's appearance and durability. This stability is crucial for creating ceramic items that meet the highest quality standards.

Moreover, the natural plasticity of kaolin allows for the development of strong, durable ceramic bodies. This characteristic is particularly beneficial in the production of pottery, tiles, and other ceramic products that require both aesthetic appeal and structural integrity. By incorporating high-resistivity kaolin into their formulations, ceramic manufacturers can achieve a balance between functionality and visual appeal.

For more information on the benefits of high-resistivity kaolin, visit the product page.

Applications in Paper Coatings

The paper industry also benefits significantly from the properties of high-resistivity kaolin. Its fine particle size and platelet structure enable it to create a smooth, uniform surface that enhances printability and opacity. This is particularly important in the production of high-quality printing papers, where the ability to hold ink effectively is essential.

Additionally, the chemical inertness of high-resistivity kaolin ensures compatibility with various coating chemistries, making it a reliable raw material for paper manufacturers. This versatility allows for the creation of papers with superior brightness and ink holdout, which are critical for applications such as packaging, labels, and high-end printing.

Company Background: HEBEI NINGCHAI MACHINERY CO.,LTD.

HEBEI NINGCHAI MACHINERY CO.,LTD. is a leading manufacturer and supplier of high-quality kaolin products. With a focus on innovation and customer satisfaction, the company has established itself as a trusted name in the industrial materials sector. Their commitment to quality is reflected in the rigorous standards they uphold for their products, ensuring that they meet the diverse needs of their clients.

As a company dedicated to advancing the use of natural materials in industrial applications, HEBEI NINGCHAI MACHINERY CO.,LTD. continues to invest in research and development to explore new applications for high-resistivity kaolin. Their expertise in this field positions them as a valuable partner for manufacturers seeking to enhance their product offerings.

For more details about the company and its offerings, visit the company page.

Conclusion

High-resistivity kaolin stands out as a versatile and essential material in both the ceramic and paper industries. Its unique properties, including high electrical resistivity, fine particle size, and chemical inertness, make it an ideal choice for manufacturers seeking to enhance the quality and performance of their products. With the support of a reputable company like HEBEI NINGCHAI MACHINERY CO.,LTD., the future of this material looks promising, as it continues to meet the evolving demands of modern industry.

References

[1] National Institute of Standards and Technology (NIST). "Driving Innovation." Retrieved from https://www.nist.gov.

-

Truck Drum Brake Spring Replacement ProcedureLitabaAug.22,2025

-

Evolution Of Brake Drum Function Designs In Automotive HistoryLitabaAug.22,2025

-

Drum Brake Motor Thermal Management SolutionsLitabaAug.22,2025

-

Essential tools for brakes and drums repair jobsLitabaAug.22,2025

-

Trailer Drum Brake Self-Adjusting Mechanisms ExplainedLitabaAug.22,2025

-

Brake Drum Types in Vintage Auto RestorationLitabaAug.22,2025

-

Rear Drum Brakes Maintenance TipsLitabaAug.04,2025